Elk-Valley 3D

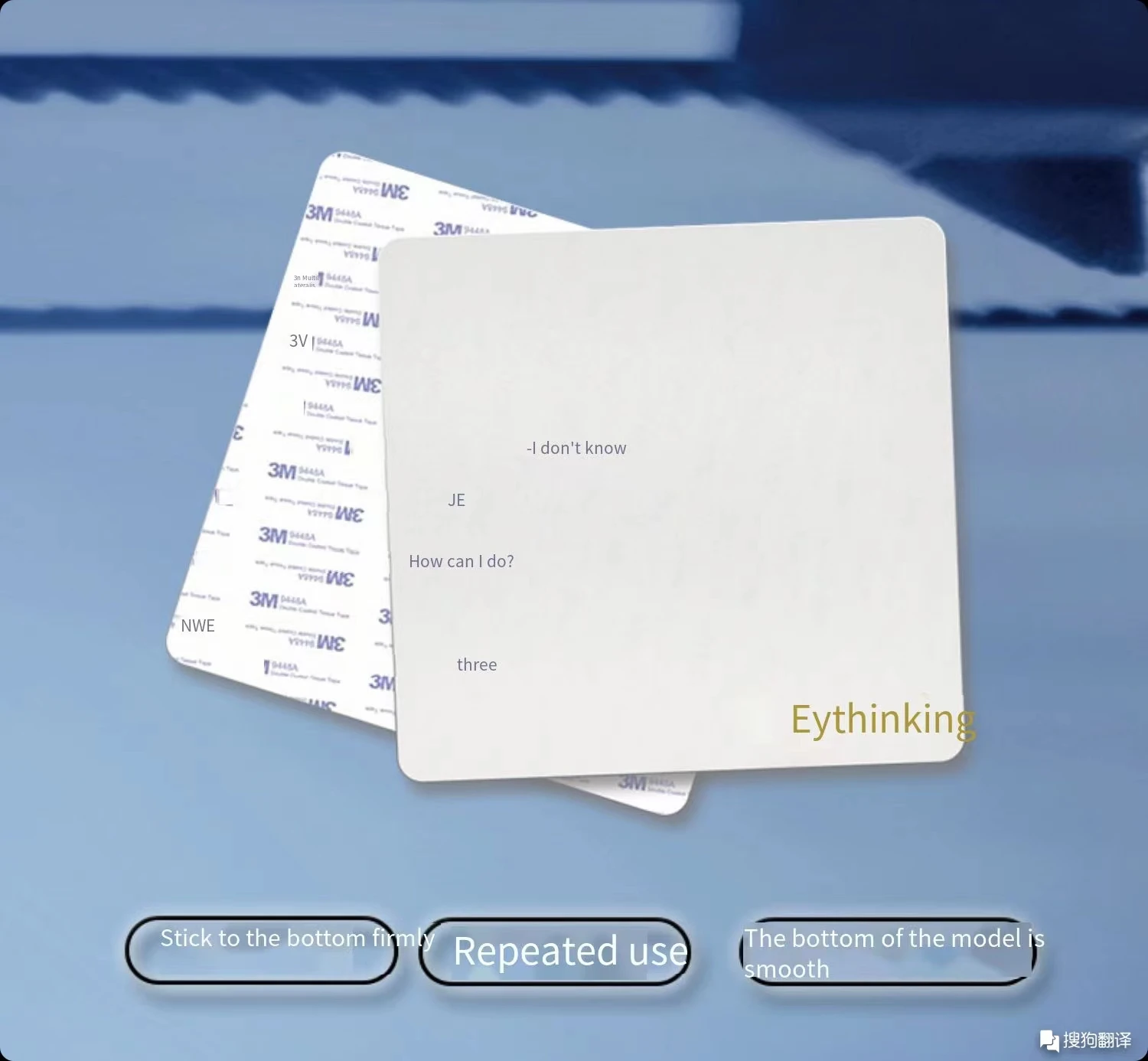

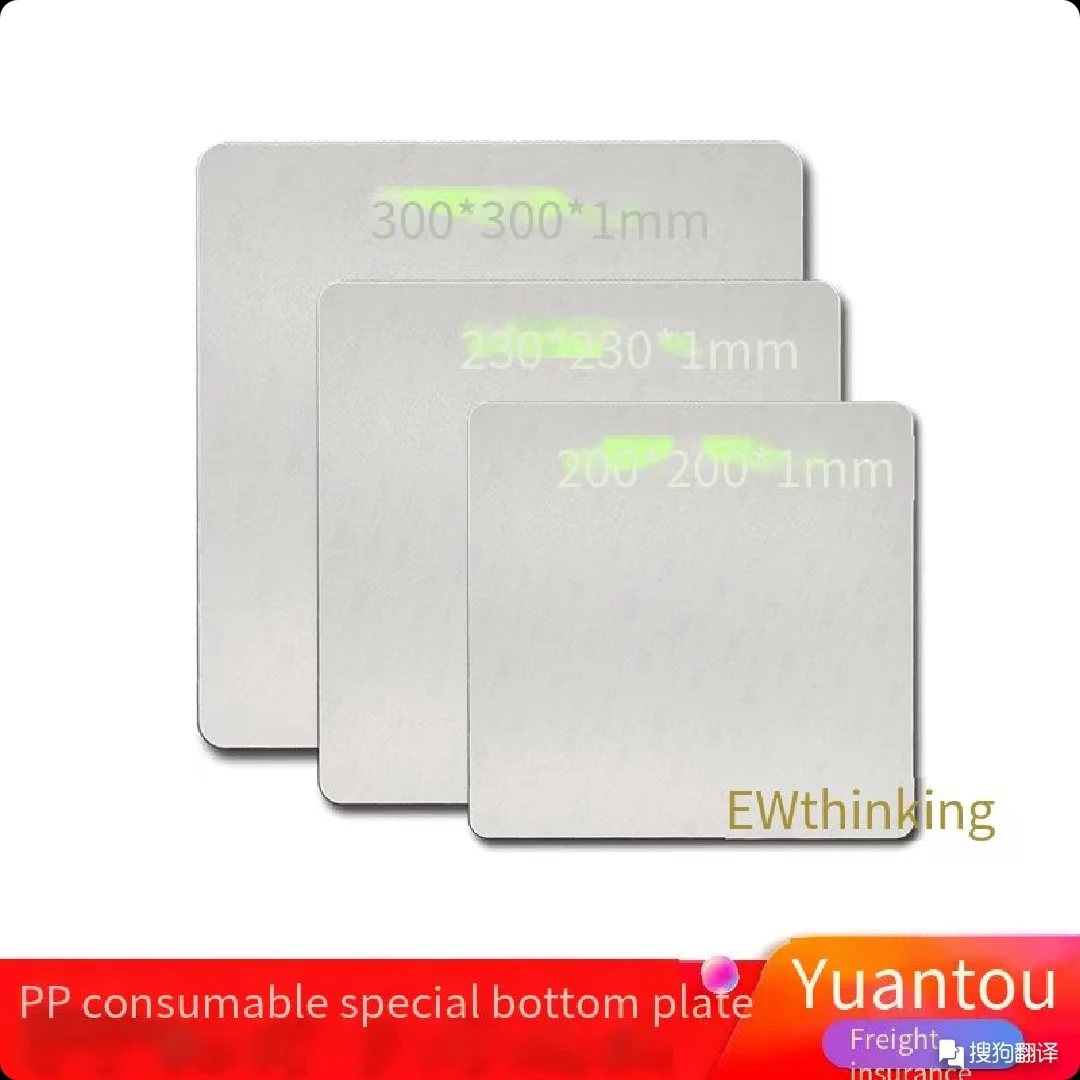

3D Printing PP Filament Special Base Plate Stick Bottom Firmly No Edge Warping Repeated Use Platform Film Easy Take Mold Parts

3D Printing PP Filament Special Base Plate Stick Bottom Firmly No Edge Warping Repeated Use Platform Film Easy Take Mold Parts

Couldn't load pickup availability

SPECIFICATIONS

Brand Name: Erilles

High-concerned chemical: None

Item Type: 3D Printing PP Filament Special Base Plate Stick Bottom Firmly

Model Number: 3D Printing PP Filament Special Base Plate Stick Bottom Firmly

Origin: Mainland China

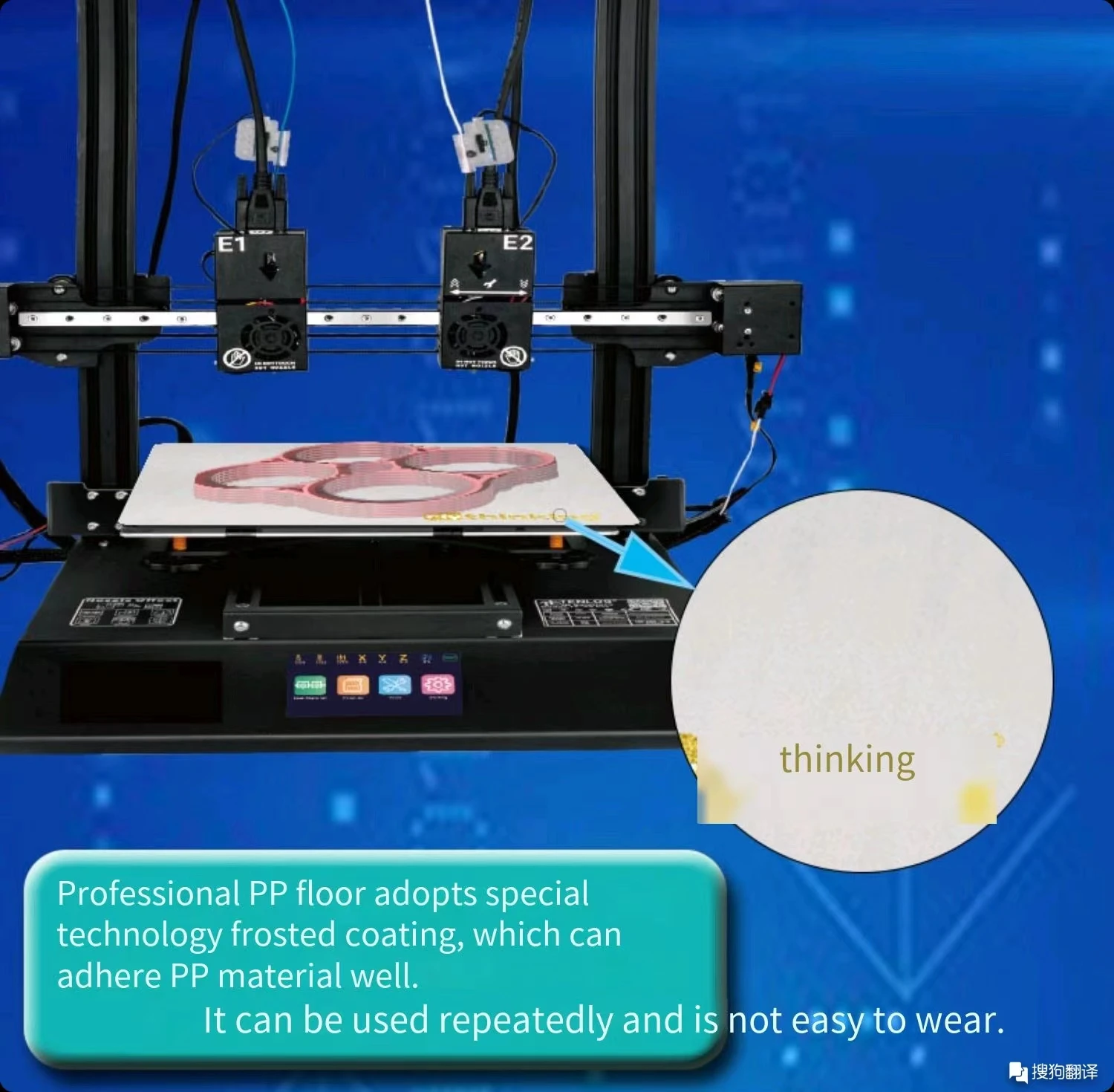

The special base plate for PP consumables is a newly developed film with special coating to solve the warping of PP materials.

Specific usage

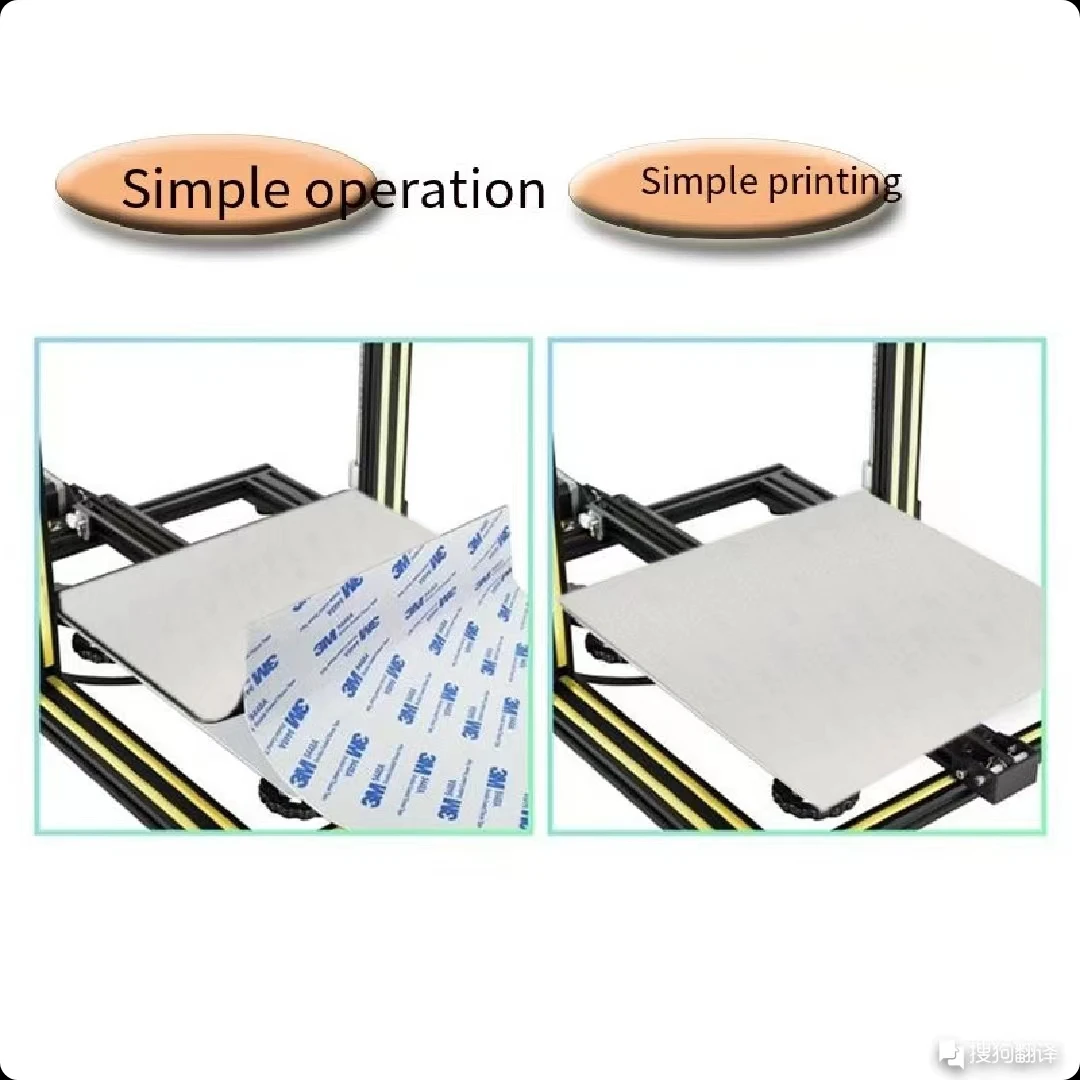

1. Thoroughly clean the impurities on the surface of the printing platform, or take a clean glass plate of appropriate size;

2. Remove the adhesive backing protective paper;

3. Fit the bottom plate neatly on the printing platform along the edge of the platform;

4. Use the scraper to scrape repeatedly for several times to make the bottom plate closely fit the platform.

5. Before printing, level the platform, and the distance between the nozzle and the PP special base plate is 0.05mm less than the thickness of an A4 paper (you can use an A4 paper to level it first, and then adjust the balance screw through Wang Dong after printing, and fine tune it to make the nozzle closer to the base plate).

matters needing attention

1. Before fitting the base plate - be sure to clean the impurities and chemicals on the surface of the printing platform to avoid affecting the printing effect. It is recommended to use - pieces of plain glass or steel plate with smooth surface;

2. When pasting, stick slowly along the edge, and cooperate with the scraper to avoid sticking bubbles;

3. This base plate is specially used for PP consumables. Printing directly on this base plate does not need additional coating;

4. When printing, the special spray pant and the bottom plate are adjusted to the appropriate height. When the nozzle is too far away from the bottom plate, it is not easy to stick to the bottom, and when the distance is too close, it may cause damage to the bottom plate and it is not easy to take the mold;

5. The bottom plate does not need to be heated during printing. In special cases, the heating temperature should not exceed 60 degrees, and D is not glued or deformed (the temperature is set according to the actual printing situation).

Share